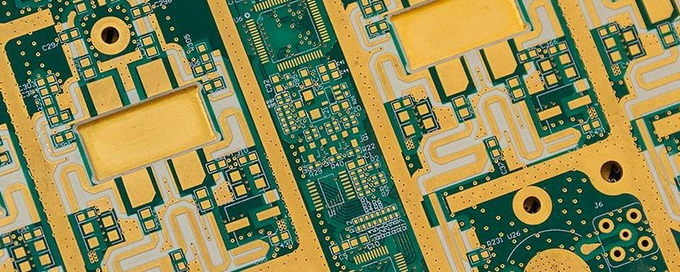

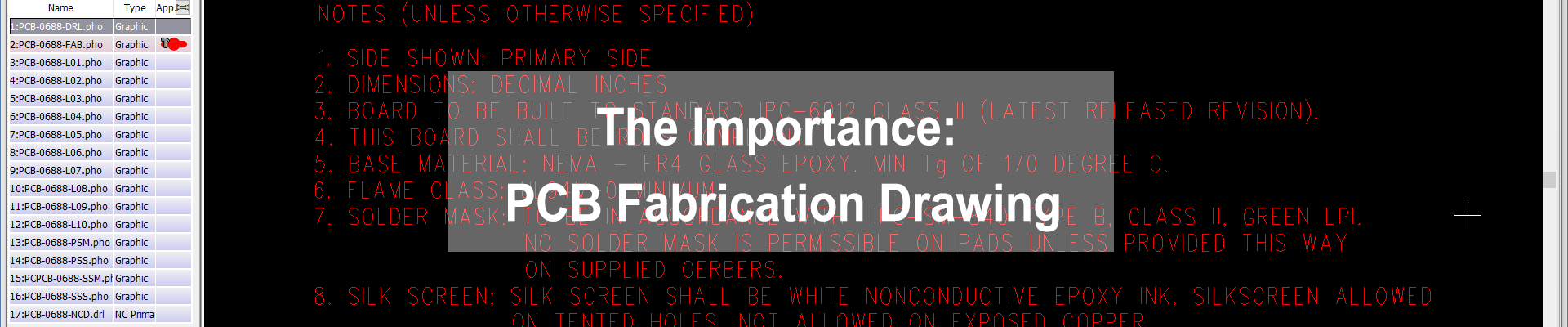

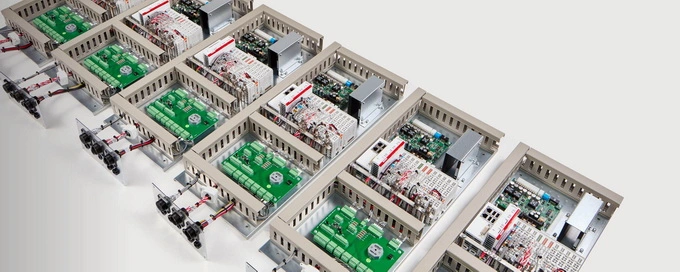

Printed circuit board assembly

Integrated solutions & added services

Market We Serviced

With over 20+ years experience working in exceptional printed circuit board manufacturing and PCB assembly, everything we do revolves around focus on high mix & low volume electronics manufacturing services and larger OEMs. We have been keeping providing optimal services by our thorough understanding of your project and it’s market. Our confidence of know-how to manufacture it at insurance quality under minimum cost and time can help to reduce the risk to overall your business. To that end, our many years concentrating on below eight specific markets will be around to support you for many years to come.

NO MOQ

Detail

Advanced Capabilities

Detail

100% Quality Guarantee

Detail

Absolutely Flexibility

Detail

Real One-Stop Solution

Detail

Professionalism

Detail

Know-How

Detail

Flexibility

Detail